- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Binciken gwaji na aikin paninatiatic na parsients daban-daban

2025-06-19

ATsarin aiki na pnaneatic, matsin lamba na gradient ne mai mahimmanci siamare wanda ke bayyana yanayin gas da barbashi mai ƙarfi a cikin bututun. Yana nuna cewa kai tsaye yana nuna yawan amfanin makamashi da ake buƙata don shawo kan juriya yayin isar da tasirin isar da tasiri sosai, kwanciyar hankali, da tsada. Saboda haka, bincike mai zurfi akan tsarin aikin na yau da kullun yana da mahimmanci don ingantaccen tsari, inganta haɓakar aiki, da rage asarar makamashi, da rage yawan asara. Wannan labarin ya gabatar da bincike game da gwaji game da bambancin girman gradient tasiri akan aikin panematic.

Asali na asali na isarwa & matsin lamba

Yadda yawan isar da ayyukan pnematic

Tsarin aiki na pnaneaticDa farko amfani da kayan aikin iska (misali, busa, ɗakunan motsa jiki) don samar da babban saurin iska, propelling kayan ƙasa ta hanyar da aka rufe su. Dangane da tsayayyen tsararren gas da gudu, an rarraba shi cikin manyan nau'ikan manyan abubuwa:

- Tsarbar lokaci-lokaci yana isar da kai: Lowarancin mai-gas, mai ƙoshin gas, an dakatar da barbashi a cikin iska. Daidai ne ga ɗan gajeren nesa, canja wurin abu mai yawa.

- A tattseting-lokaci yana isar: babban mai ƙarfi, ƙananan gas mai gudu, barbashi suna motsawa cikin matabbata ko yadudduka. Ya dace da dogon nesa, babban iko, ko kayan ɓarna / farantin jini.

Matsin lamba da m

Matsin lamba (an auna shi a PA / M ko KPA / M) yana nufin canjin matsin lamba a kowane ɓangaren bututun bututu. A cikin pnaneatic isar, yana nuna asarar kuzari saboda gogayya, nauyi, da juriya.

Mabuɗin tasirin matsin lamba:

- Amfani da makamashi: manyan gradients suna buƙatar ƙarin iko daga ƙwanƙwasawa / masu ɗakuna.

- Tsarin kwanciyar hankali na gudana: mafi kyawun gradients suna tabbatar da tsayayyen kwarara (E.G., Ingantaccen ƙarfin-lokaci). Ma low → clogging; maɗaukaki → watsar da iska & kuzari.

- Isar da ƙarfin: A cikin wasu kewayon, ƙara yawan gradient inganta kayan abu.

- Lalace-iri & bututun fasali: mafi wuce gona da iri ƙara yawan barbashi da bututun mai.

Hanyoyin gwaji & Ayyukan Aiwatarwa

Saitin gwaji

A hali na pnaneatic isar da rig ya hada da:

- Isar da iska (busa, ɗakunan motsa jiki)

- Tsarin Ciyar da (Screy Feeders, Badukan Rotves)

- Isar da bututun ruwa (m don lura da gudummawa)

- Gas-mai ƙarfi (hayewa, matattarar jakar)

- Yin nauyi & tarin (auna kayan aiki mai kyau)

- Sensors & Daq tsarin:

- Matsin lamba (gida / gida / duniya)

- Mita na kwantar da (ƙarar gas)

- Matsayi mai nauyi (LDV, PIV)

- Hotunan zazzabi

Maballin aiwatarwa

- Jimlar matsin lamba (Δp Jime ) = etp G )

- Matsin lamba (Δp / l) - Core sigogi (p / m)

- Ratearancin taro mai ƙarfi (m s ) - kg / s ko t / h

- M-gas-gas rabo (μ) = m s sub> g

- Yawan kuzari (E) = shigarwar wuta / M S

- Barbashi Breaking & butoteline saka kudaden

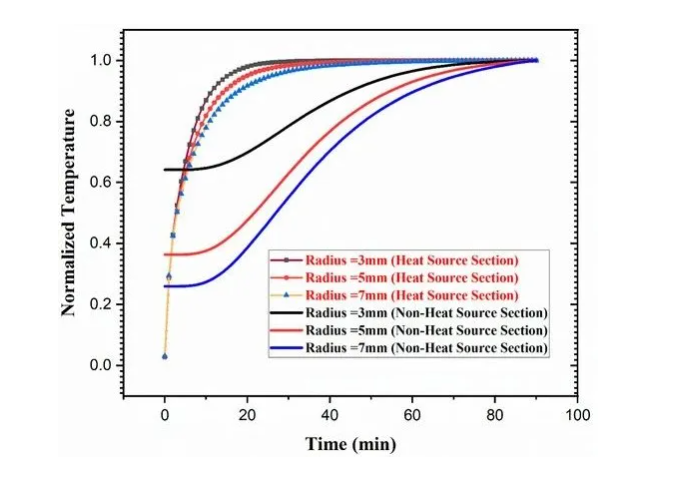

Binciken gwaji na gwaji

- Matsin lamba vs. isar da iko

- Yana kara masara (ta hanyar iskar gas / mai ƙarfi) tana haɓaka kayan aiki na kayan, amma ba layi ba ne.

- Misali: Don elm 2mm filastik a cikin bututun ruwa na 100mm, na kiwon ΔP / l daga 100 zuwa 300 pa / m 1 t / h. Karin ƙara da yawaita rage raguwar dawowa.

- Tsarma-lokaci: ƙananan gradients haɗari mai haɗari; mafi kyau duka gradients suna tabbatar da dakatarwar tsayayye.

- M-lokaci: gradients a ƙasa 150 p p / m ya haifar da clogging; 250-350 pa / m kiyaye kaffun kifi mai gudana; > 450 pa / m narkar da matosai zuwa tsarfi.

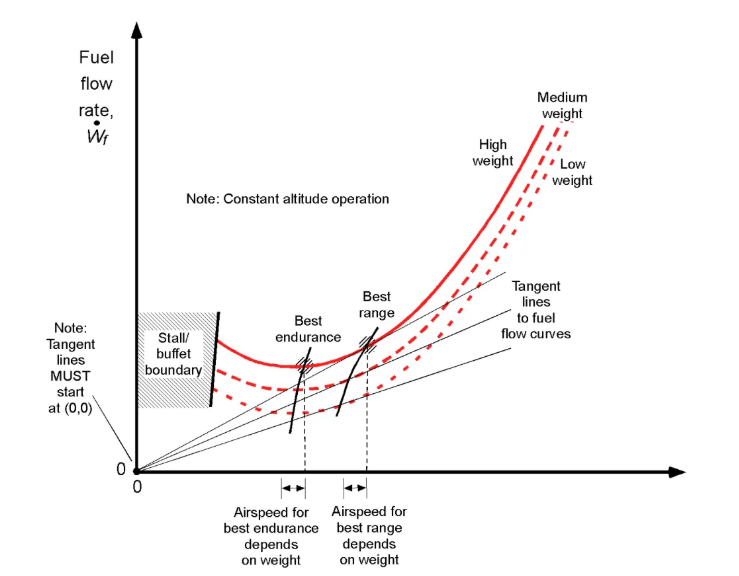

- A U-dimbin yawa valve gradient (Δp / l) da yawan kuzari (E).

- Misali: Tsarin nesa wanda ya samu ɗan ƙaramin ƙarfin kuzari na ƙasa (5 KWH / t) a ΔP / L = 50 KPA.

- Babban gradients (E.G., 400 vs. 200 pa / m) Breadage gilashin Breadage (0.5% → 2.5%) da kuma bututu mai sa.

- Matsayi na hawa (bincike na gwaji) alamar alama (misali, clogging hadarin).

Ingantaccen Ingantaccen Injiniya

- Designira & Zabi: Match Gradient Yanges zuwa kayan abu (rabo, sabani) da nesa / bukatun nesa.

- Ayyuka na aiki: Daidaita ragin iska / Ciyarwar abinci don ci gaba da ΔP / l a cikin "Spot Spot" don inganci.

- Ikon Smart: Iot Sunsors + AI-Tura PID madaukai don ingantaccen ingantawa na yau da kullun.

- Sanya Mitsigation: Yi amfani da bututun ruwa mai nauyi ko ƙarfafa lanƙwasa don kayan ababen rai.

- Kayan gyara na kayan: ƙara kayan aikin kwarara ko canza bututun bututu don canza bukatun gradient.

Kammalawa da gaba na gaba

Wannan bincike na gwaji yana nuna yadda matsi da manyan gradients masu tasiri tasiri ga ingantaccen isar da pnumatic, kwanciyar hankali, da tsada. Gudanar da Gudanar da Gudanar da Ai-Powered da tsarin daidaitawa na lokaci-lokaci suna yi wa Readaddamar da Ci gaba, kofin kore, isar da mafita.

Game da yinchi

Shandong Yinchi kariya na kare muhalli Co., Ltd.(Yinchi) ƙwararrun ƙwarewa a cikin ci gabaTsarin aiki na pnaneaticda kuma amfani da kayan aiki na kayan aiki. Tsarinmu na R & D-D-d-driven suna tabbatar da makamashi mai inganci, mai karamin aiki a kan masana'antu.

Tuntube mu:

📞 86-1885314775 | ✉ sddcmachine@gmail.com